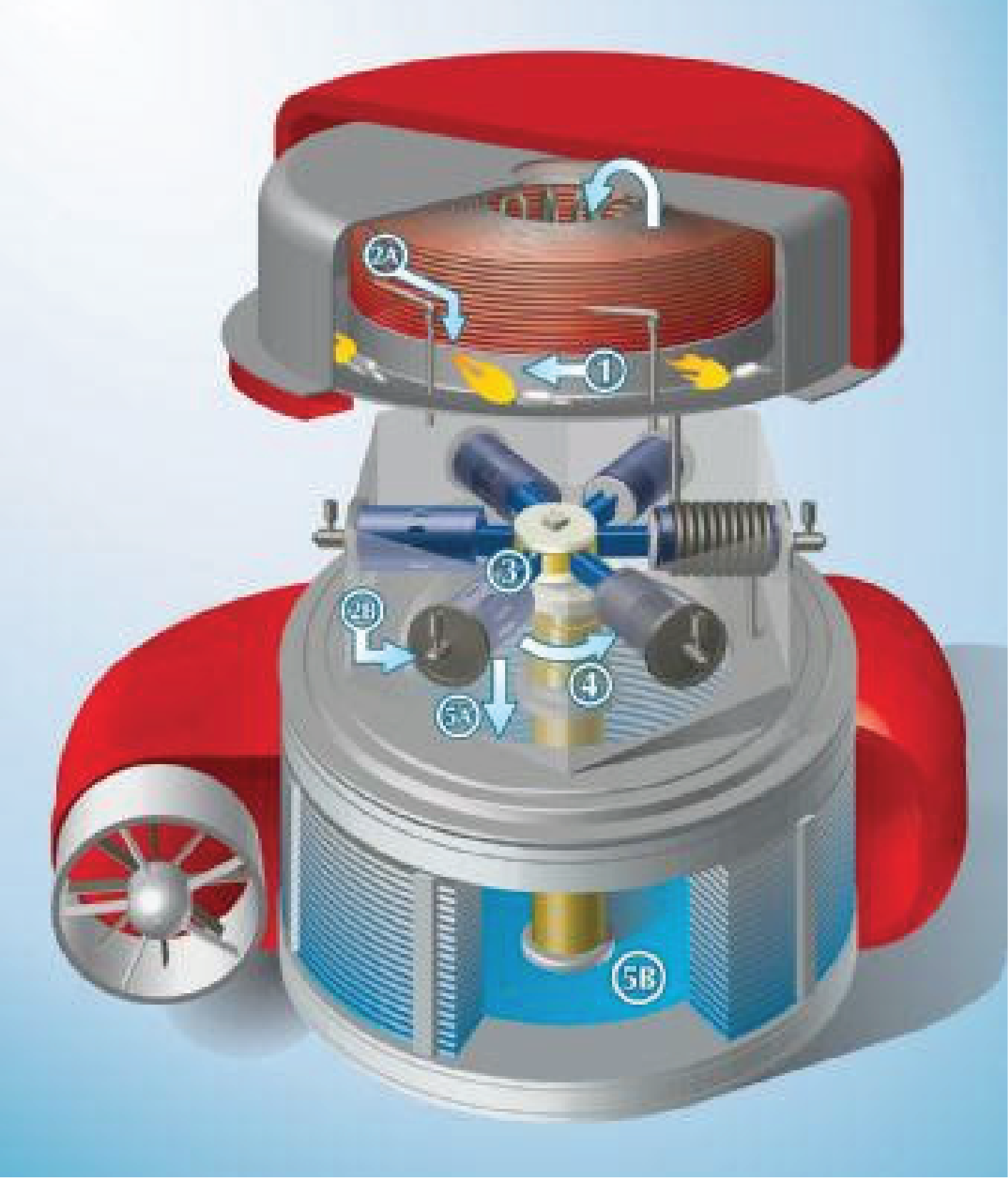

About The Engine

Heat Process

- Fuel is atomized and burned in a patented centrifuge combustion change or heat from a different heat source.

- Superheated steam (a) enters cylinders (b) through an advanced value system (not pictured).

Mechanical Process

- Steam enters cylinders under pressures to 3200 psi.

- Six radial pistons on a patented spider bearing turn the crankshaft.

Cooling Process

- Steam escapes cylinders (a) condensing into water (b) collecting in sealed pan.

- Blowers force air through the condenser to speed cooling process.

Regenerative Process

- Combustion air is pre-heated from (a) condensing unit and (b) exhaust ports.

- Water is preheated by (a) passing through coiled tubes around exhaust ports of cylinders before (b) entering primary heat exchanger coils restart cycle.

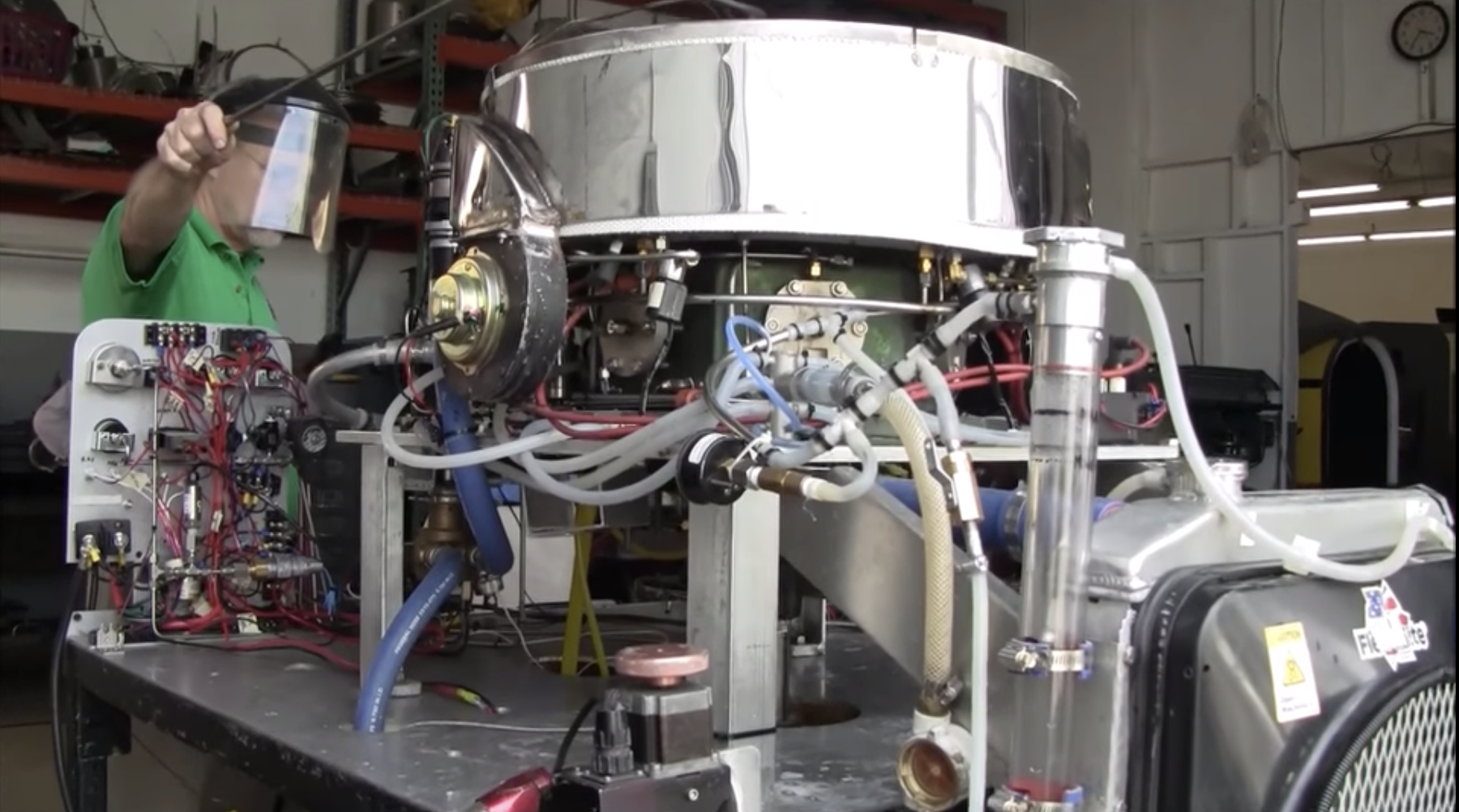

Water-lubricated 6 cylinder engine

- generates extremely high front-end torque in a compact, lightweight package.

Condenser with air-cooling

- compact, efficient, and closed-loop (no top-off).

Three heat regenerative processes

- increases engine efficiency.

All Fuel combustion chamber burns cleanly completely to create super-heated steam in layers of coils. No pressure vessel.