History

Our Origin

Before inventing the features that make the Cyclone engine so desirable, Harry Schoell’s innovations included faster, more stable boat hull designs that would plane out sooner and with less horsepower than existing designs, developed and built at his Schoell Marine facility, founded in 1967. Schoell also designed and patented “Surface-Drive Propellers” and Pulse- drive propellers for efficiency improvements, and has nearly 50 patents to his credit.

The Cyclone Advanced Rankine Cycle engine has been in research and development for almost 20 years. Cyclone has held over 30 patents worldwide on its technology. The engine technology has evolved and matured, thanks to the pioneering work of inventor and Cyclone Chief Technical Officer Harry Schoell, along with the support of many past and present investors, staff, and technical advisors.

The proof of concept was a single cylinder engine tested and run on several fuels. The next hurdle was technical 3 rd party validation, which the engine design received from Oren Masory, PhD and Homayoon Amir Abtahi, PhD, professors at Florida Atlantic University (thermodynamics and mechanical engineering), on October 26th, 2004.

Their evaluation concluded that the design could lead to higher overall efficiencies, utilize a variety of fuels with low pollution levels, conventional lubricants would be eliminated, the engine’s combustion chamber is innovative, the centrifugal design for airflow and condensing is promising, and the compact design has potential for a variety of mobile and stationary applications.

Cyclone Power Technology LLC, was formed, and on September 14, 2005, Harry Schoell filed for the U.S. patent on the Cyclone “Heat Regenerative Engine”, and R&D began. Over the subsequent years, Cyclone evolved and tested advances in materials and design, successfully producing significant efficiency improvements and reductions in the number of engine moving parts, increased durability and engine life, and lower manufacturing and maintenance costs.

Awards & Validations

Cyclone has received many awards and accolades for its Cyclone engine, including Society of Automotive Engineers (SAE) 2006 and 2008 Tech Awards and Popular Science Invention of the Year in 2008. A sample of these awards and accolades are pictured below.

Project Delivery

In 2014, the 15hp Cyclone S-2 was successfully incorporated into a 10kW genset for the US Army. The following is an excerpt from an article published by Karl A. Petersen [then Vice President of Product Development for Cyclone], in the Steam Automobile Club of America’s Volume 28, No. 5, September – October, 2014 issue of the Steam Automobile Bulletin, documenting the success of that project.

“POMPANO BEACH, FL, May 29, 2014. Cyclone Power Technologies Inc. (OTCQB: CYPW), developer of the all-fuel, clean-tech Cyclone Engine, announced that it has successfully delivered its prototype S-2 engine and auxiliary power unit (APU) to the U.S. Army / Tank Automotive Research, Development& Engineering Center (TARDEC), in full satisfaction its $1.4 million development contract with the government.”

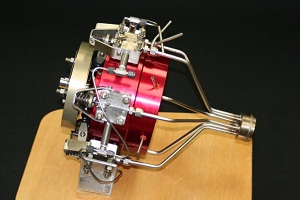

Cyclone successfully met the objective of the TARDEC program to develop a Phase I prototype of a highly compact (12” 12” x 17”), lightweight 10kW power generator, driven by Cyclone’s 15hp multi-fuel-capable external combustion engine.

As part of the delivery, the Cyclone powered APU ran at the TARDEC test cell outside of Detroit, MI while connected to a fuel supply and an electrical load cell. Representatives from TARDEC confirmed that the system met contract requirements.

These following photos are of the delivered genset getting the final checkout before boxing it up to take to TARDEC.

None of the components could be bought off the shelf; not the pumps, atomizing air compressor, coilstack, engine parts, feed pump, flat plate condenser/radiator, alternator. Because this was a “Development” program, it meant that most of these items were designed and tested and optimized and built again, several times. When this technology is compared with others, it is clear that even after 400 years of steam power and 100 years of Internal Combustion engine development, there is no other 10kW genset available of the same size or weight – which will run on multiple, mixed, gaseous, liquid, and solid biofuels – does not need hydrocarbon lubrication filled and changed, – is a fully condensing closed cycle, and could be converted to produce Zero Carbon Power from Concentrated Solar Thermal Energy.

Technical Description, Innovation, and Impact

Versions of steam automobile engines since the early 1900s had efficiencies that ranged from less than 10% to perhaps 18-20% net cycle efficiency, at best. Wikipedia reports that the Doble Steam Car got 15 miles per gallon despite its 5000 pound weight. However, to achieve higher efficiency, steam temperature and pressure needed to be increased. Limiting all previous vehicle engine steam temperatures was the use of injected cylinder oil, which had to be kept below the carbon formation temperature of typically 650 – 750 degrees F. The Cyclone engine has eliminated the use of oil in the engine, replacing it with deionized water and advanced high temperature lubricant-free bearing materials. This combined with the latest materials and technology eliminates the upper temperature limit, allowing operation at 1200-1400 degrees F, greatly improving the cycle efficiency. The deionized water also serves for internal engine cooling. In an operating vehicle, there would be further relative energy/fuel savings associated with fact that the engine can be directly connected to the drive, without the need for a transmission, as well as the engine’s ability to self start (no fuel burned when the vehicle stops moving).

Overall Impact on Advancing the State-of-the-Art

The Cyclone engine is an ideal fit for propulsion of watercraft. The following is a picture of the boat that Schoell designed and built specifically for the Mk-5 engine to attempt to break the existing steam water speed record (WSR). A full-size mock-up of the Mk-5 engine is shown in the boat. Pictured below is the Cyclone-designed and built Mk-5-based Land Steam Speed Record attempt vehicle.

Both the WSR Boat and the LSR car are housed at Cyclone Power’s Longview Texas R&D Facility. Cyclone now operates from an existing 3,573 square foot R&D facility in Longview Texas (pictured below). The facility has three offices, a deep loading dock, and three additional roll-up doorways.

R&D Facility

The Cyclone R&D Facility in Longview Texas. Located at:

100 Tex Pack Street

Longview, TX 75604

Phone: 1(954) 610-0910